Technical Data

Weight

35kg

Max temperature

Up to 1133°C

Fire resistance time

2 - 4 hours

Thermal expansion

0.01562mm per mm at 1100°C

Spread of Flame

Class 1 (BS 476 Part 7)

Fire Propagation

Class 0 (BS 476 Part 6)

Shelf life

12 months

Standards

ISO 6944, BS 476 Part 24, AS 1530.4, UL 723, LPCB

Construction

FLAMEBAR BWl1 Fire Duct is constructed from galvanized sheet steel manufactured to the HVCA or SMACNA standard, the degreased and factory fire sprayed with FLAMEBAR BWll which is a specially formulated water-based compound. This contains selected mineral filters in a low permeability elastomeric binder to a thickness of approximately 0.7mm to give a finished product that has been successfully tested for international use under Cellulosic Fire Conditions over 4 hours duration. Ductwork is produced in sections and is assembled on-site utilizing tested fireproof gaskets/sealants.

Flamebar BW11 and accessories

The unique properties of FLAMEBAR BWl1 have enabled us to design a low density, highly durable material which accommodates induced stress arising from extreme and varying conditions eg Climatic Moisture and Structural Loading Variations and the effect of thermal shock during a fire.

The completed system has been tested accredited by BRE to BS 476 Part24 (1987) and also classified by UL to ISO 6944 (1985) (2008) up to a temperature of 1133°C.

System Advantages

The FLAMEBAR BW11 system offers the following advantages:

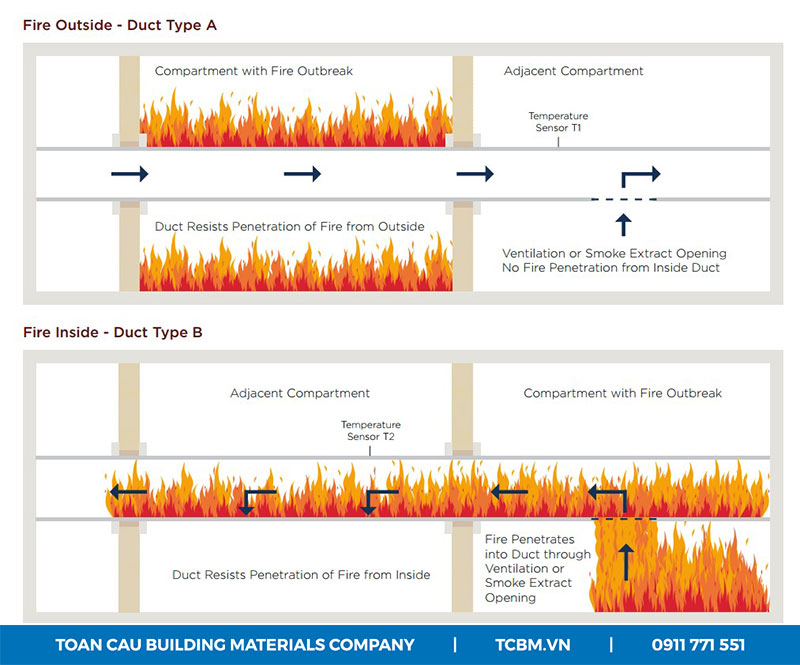

The system is tested for up to 4 hours for Stability, Integrity and Insulation following BS 476 part 24 and ISO 6944 for both type A and B fires.

Flamebar BW11 Fire Rated Ductwork

As well as being used for Fire Rated Smoke Extract, Kitchen Exhaust and Pressurisation Systems, the FLAMEBAR BW11 system can also be used instead of drywall fire rated shafts.

By eliminating drywall shafts, floor space is maximized and as FLAMEBAR BW11 is both water and mould resistant, the Fire Rate Shaft can be constructed before the building is completely watertight, thereby reducing construction time and greatly reducing the need for additional site inspections.

The FLAMEBAR BW11 ducts arrive on site as finished sections ready for installation.

As the FLAMEBAR BW11 system can be based upon DW144 or SMACNA ductwork construction standards the fire duct sections can be constructed using the TDF or slide-on flange system, jointed together incorporating the FLAMEBAR Intumescent Gasket, the installation can be carried out by competent duct erectors.

Plant items such as in-line fans and silencers, subject to casing thickness and suitable construction, can be sprayed with FLAMEBAR BW11 and thereby rated as part of the certified system eliminating the need for special enclosures.

The FLAMEBAR BW1 1 system is the lightest-weight certified system on the market. Therefore as well as the load on the structure being eased, handling and site erection is made easier.

Advantages

Flamebar BW11 is a water-based, fire-resistant compound that is sprayed directly on the sheet metal, ductwork components. Once the spray is applied, the treated ductwork is cured and sealed so that the coating does not peel, flake, or deteriorate. In the event the coated ductwork suffers damage before inspection, a factory-supplied touch-up kit is readily available for job site repair.

Fire Rated Ductwork

- Flexibility in design and ease of application: Flamebar BW11 offers complete flexibility in design-rectangular, flat oval and circular ducts are available.

- Easy to install: Can be easy to apply Flamebar on ductwork both on the ground or on installed ductwork. Can be done both in site and factory. Can be installed both vertically or horizontally for a completely versatile application.

- Space Saving and lightweight: Only an additional 1 .5kg/m2 average base on 0.7 mm thick coating and only 1 mm thickness (particularly for smoke extract ducts).

- Cost-efficient: Almost no material waste. And saving labor costs much more than any materials.

- A complete and internationally tested/certificated fire rated ductwork system, Certified upon final inspection. Flamebar BWl1 has been tested and approved by: ISO 6944, BS Part 24, AS 1530.4, UL Accreditation (online), LPCB 3rd party Accreditation (online) and the local fire department also.

Fire Rated Ductwork

Standards

The range of FLAMEBAR BW1 1 Fire Duct has been tested by the Loss Prevention Council by BS 476 Part24 (1987) and ISO Standard 6944 (1985) (2008), for vertical and horizontal ductwork, with fire inside and outside the duct, more than 4 hours Stability, Integrity and Insulation for ventilation ductwork, smoke extract ductwork or kitchen extract ductwork. FLAMEBAR BW11 has been tested by UL in the USA to determine compliance with NFPA 90A (Installation of Air Conditioning and Ventilation Systems) for flame spread and smoke development with the following results:

| NFPA Stipulation | Flame Spread not to exceed 25 | Smoke Development no higher than 50 |

| FLAMEBAR BW11 Results | 9.4 | 0.2 |

Test conducted by UL Standard 723 “Test for Surface Burning Characteristics of Building Materials” (ASTM E84).

FLAMEBAR BW11 Fire Duct has also passed the hose stream test to ASTM – El 1 9 with a water pressure of 207 KPa (30 psi) for 2½ minutes.

Properties

ExteriorWeathering of FLAMEBAR BW11 Fire Duct Duplicate samples were placed on the exterior weathering frame and left exposed from January 1 993. The results so far show:

- Some dirt pick-up which can be cleaned off.

- No mould growth.

- No chalking.

- Materials has remained totally intact.

Considering the length of time the samples have been exposed, the material is in good condition.

The surface of the fire rated ductwork

Artificial Weathering oi FLAMEBAR BW1 1 – OUV Weatherometer

The samples undergoing artificial weathering has undergone over 22,000 hours of alternate UV and condensation cycling which is extremely excessive in duration terms. 22,000 hours is equivalent to 60 years of external exposure.

Expansion to FLAMEBAR BW11 Fire Duct

As all steel expands with temperature, there will naturally be an expansion of the fire duct under fire conditions as follows:

- At 1100°C an expansion of 0.01562mm per mm (0.016 in per in).

- At 600°C an expansion of 0.00852mm per mm (0.008 in per in).

- At 430°C an expansion of 0.006106mm per mm (0.006 in per in).

Firespray provides a full system for fire rated ductwork. Flamebar BW11 system can be based upon DW144 or SMACNA. Besides coating, ductwork must be used fire rated sealant and Intumescent Gasket.

Contact TCBM at hotline 0911 771 551 for advice and quotation.

Tiếng Việt

Tiếng Việt