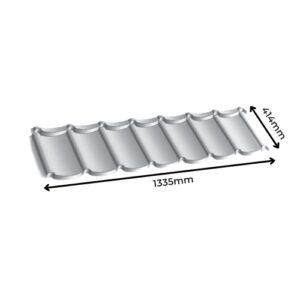

Technical Data

Length

1000mm

Width

340mm

Thickness

3.3 / 6.6 ±10%

Water Absorption

<1%

Tensile Strength

>800 / >600 N/50mm

Weight (Finished Product)

13 kg/m² ±10%

Reaction to Fire

E (EN 13501-1 / prEN ISO 11925-2)

Reference standard

EN 544

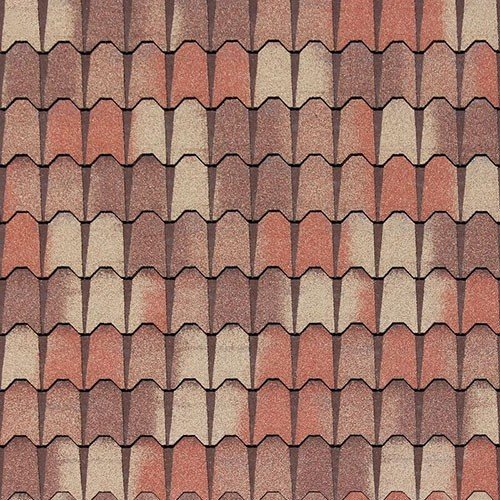

Introduce Master Coppo

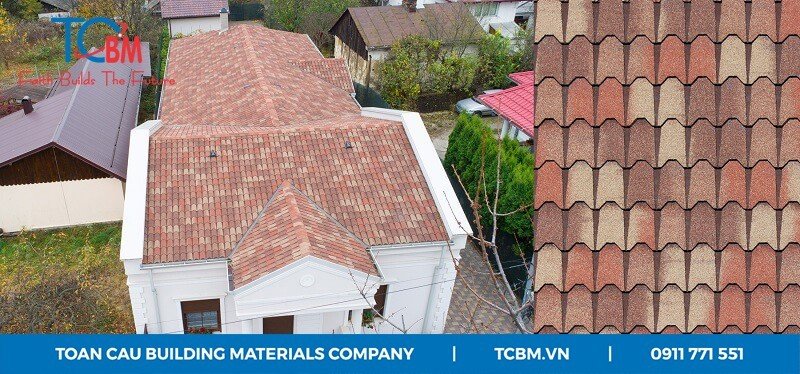

The new shingles “Master Coppo” is an innovative solution in the roofing industry. It offers the aesthetics of traditional brick tile roofs and will be possible to meet the unique architectural needs of the historical and rural contexts.

Master Coppo is the only patented, thermoplastic shingle, laminated in a double layer, that thanks to the 3D effects and to the nuances of colors specially designed for the different layers, allows recreating on the roof this particular aesthetic-effect.

“Performance” benefit:

– Not subject to breakage and can be walked on.

– Lighter compared to other coverage systems and easy to install. Contributes to the reduction of the effects of an earthquake on the building.

– Fixing the system with nails or by heat, even on very sloping roofs, avoiding the risk of slipping.

– A guarantee of durability and stability over time the color.

– Weather resistant, resistant to UV radiation, blistering, frost resistant, and even hail.

– Ability to adapt to various roof shapes.

– No maintenance.

– Sound insulation: it is not noisy when it rains.

Benefit “for the environment”

– The material is free of asbestos, tar compounds, and other dangerous substances.

– The production cycle is powered by electricity from renewable energy sources, with two photovoltaic plants for a total of 350 kWp, and a co-generator for heat recovery from the plant itself.

– The production plant is energy-efficient.

– Master Coppo shingles are lighter than other roofing systems, therefore they require less fuel to transport them, as each camion can transport more m2 of finished roofing.

– The industrial processing cycle ensures minimal production waste.

– The shingles are made with a percentage of recycled material.

– The installation system for our shingles minimizes waste at the worksite.

– Product waste can be recycled, for example, into asphalt.

Application

Application on pitched roofs, with a slope between 5° and 85°. Installation temperature above +5°C. Always check the adhesion of the pads or of the shingle at the end of the installation.

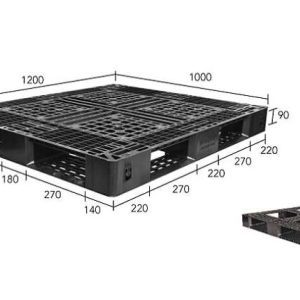

Storage

Store pallets in closed warehouses, away from heat sources and direct sunlight. Store in the original packaging. Do not stack pallets.

Contact TCBM at hotline 0911 771 551 for advice and quotation.

Tiếng Việt

Tiếng Việt