Technical Data

Toan Cau Tegodeck OSB Tongue & Groove

2250mm x 600mm x (12mm, 15mm, 18mm

Toan Cau Board OSB/3

1220mm x 2440mm x (9mm, 10mm, 11mm, 15mm, 18mm)

Tolerance of width

± 3mm. Length: ± 3mm. Thickness: ± 0.8 mm

Parallel tolerance

1.5 mm/m. Original square tolerance: 2 mm/m

Moisture content

12%

Formaldehyde content

Class E1 EN 120, max 8mg/ 100g

Standard

EN 13501-1, EN 13986, EN ISO 12572, EN 310, EN 1087-1, EN 319, EN 1087-1

Introduce Toan Cau OSB Board

OSB stands for “Oriented Strand Board“ and is a wood-based product made from thin veneer strands that are bonded together with a synthetic resin.

This OSB consists of three cross-oriented layers with the surface of the board formed from strands oriented along the length of the board and the core strands arranged in cross-orientation. This crosswise orientation of the individual layers achieves a high level of dimensional stability and excellent mechanical performance.

Toan Cau OSB Board is a wooden plank that takes advantage of input materials from forest maintenance pruning and products imported from Europe.

Toan Cau OSB

Structure of OSB

- Wood chips account for 80-90%.

- Phenol-Formaldehyde (PF) or Melamine Urea Formaldehyde (MUF) glue accounts for the remaining 5-10%.

Practicality and Safety

- High load-bearing capacity and panel rigidity.

- Moisture-resistant gluing.

- Rated as safe for a point load with 100 kg man-weight between the rafters up to 600 mm distance, by EN 12871.

- Safe seal from the second row of the panels installed until the installation of the entire roof is complete.

Innovation

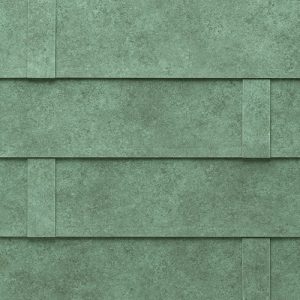

- The Toan Cau OSB Board is an ergonomic solution for fast and safe sheeting. The panel has special profiling on the edges that allows a continuous, fast, and precise installation as a rigid roof base.

- The unique combination of “L” shiplap joints and tongue and groove profile with integrated expansion space of 2 mm.

- Quick and easy installation thanks to the “fold in & slide” system or “plug in & slip”.

- Allows continuous installation thanks to the “tongue and groove” self-supporting joint on the short side of the panel.

- Cost and time-saving.

Toan Cau Tegodeck OSB Tongue & Groove

Application

Thanks to the superior features and the variety of thicknesses, OSB boards can be applied in buildings and can even be used in the kitchen or bathroom. Meet the increasing demand for use and aesthetic requirements of consumers:

- Applied as a base plate for bitumen roofing.

- Partition panels and wall cladding for offices, houses, cafes, etc.

- Making interior and exterior decorations.

Applied as a base plate for bitumen roofing

Contact TCBM at hotline 0911 771 551 for advice and quotation.

Tiếng Việt

Tiếng Việt