PIONEER UNIT

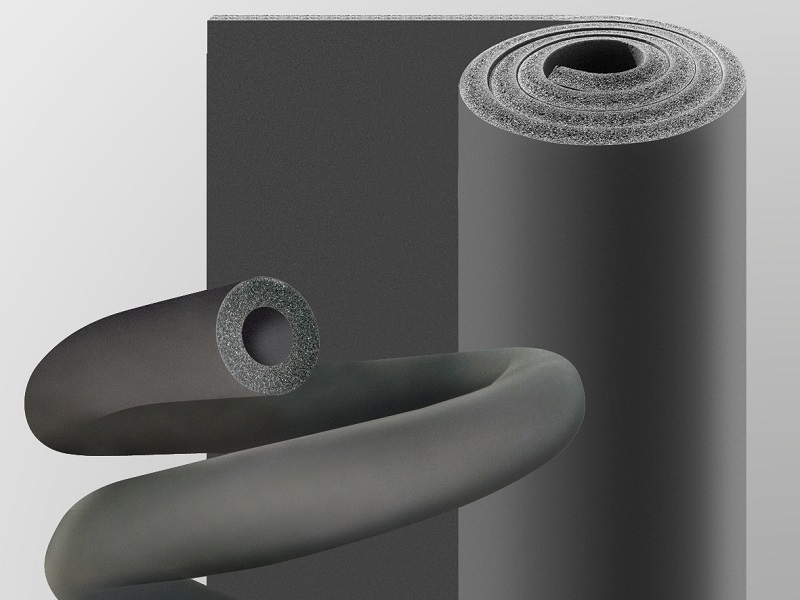

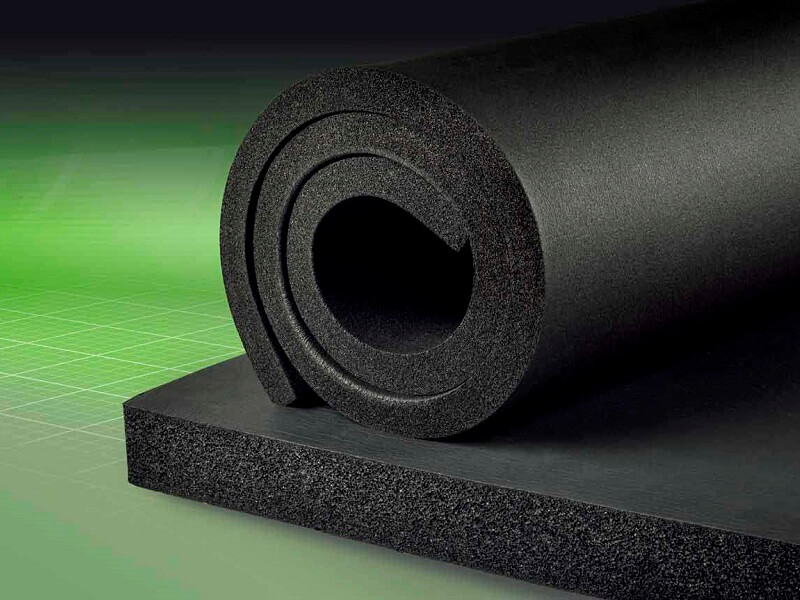

TCBM is a Pioneer unit bringing advanced building materials solutions worldwide to Vietnam.

INTERNATIONAL STANDARD

The industry leader in building material solutions of international standards.

EXCLUSIVE DISTRIBUTOR

Exclusive distributor of the world’s leading product lines.

About us

Toan Cau Building Materials Company – TCBM, a reputable construction materials supplier, is recognized for delivering top-tier imported building material solutions worldwide. With over 14 years of establishment and growth, TCBM takes pride in being a trusted partner to numerous domestic and international entities, providing exceptional solutions for construction projects.

Watch moreOUR CUSTOMER

Tiếng Việt

Tiếng Việt